1. Advanced Dispersion Technology

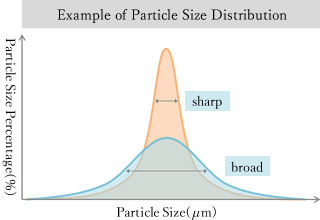

“Dispersion” means ”the powder is distributed as a single particle as much as possible while forming uniform or structure in the fluid or other components”. The process needs to be optimized based on the characteristics of raw material desired particle size distribution and that requires advanced technology.

POLYCON's dispersion technology is based on many achievements and know-how acquired since our founding. We have been developing and manufacturing products with this technology.

2. Formulation Technology to meet customer needs

The required characteristics of additives for inks or paints are various, as follows.

- Anti-blocking

- Improved slipperiness

- Enhanced abrasion resistance

- Matte effects

- Improved heat and chemical resistance, etc.

POLYCON develops products that meet these requirements.

We design the most suitable formulations by consulting the customer's requirements, based on the wax characteristics as well as the available solvents and non-volatile.

3. Production technology based on PDCA cycle

Even if the best quality is achieved in the laboratory, it is useless without stable control of the same quality and continuous mass production.

In order to achieve stable particle size distribution, POLYCON has installed several original dispersing machines. We are also improving our production technology by strictly enforcing the PDCA cycle.

4. Environmental Technology

With some organic solvents, such as toluene and xylene, increasingly being regulated for use, the needs for alcohol-based solvent dispersions are increasing.

POLYCON has been actively developing environmentally conscious products for instance IPA based dispersions.

We have constructed the independent production line for IPA-based dispersions, with strict controls to prevent contamination from other lines.